Product Video

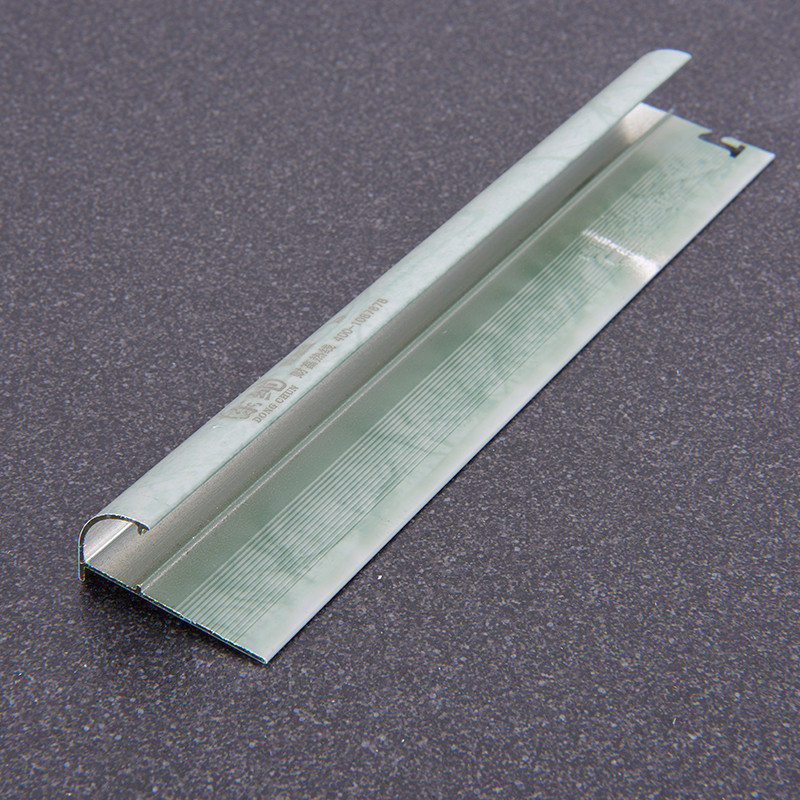

Aluminum tile trim, Model No.: X9, Open type, Width: 32mm, Height: 12.49mm.

The product is made of high-quality aluminum alloy material. After being formed by hot extrusion, aging treatment is applied to improve the hardness and strength. The surface treatment is sprayed and thermal transfer printed.

Carefully selected high-quality aluminum alloy raw materials. Aluminum alloy has the characteristics of light weight, high strength, not easy to corrode, free section design, easy to form and so on.

Waterproof and anti-corrosion. The aluminum material is treated by two processes of hot and cold during the production process, which has strong corrosion resistance.

Processing: Length cutting, Punching, Anodizing, etc.. Different processes show different effects.

Spraying treatment: The surface is sandblasted and oxidized and colored, and the color can be customized according to customer requirements.

Welcome to drawings and samples, professional customization, quality assurance.

You can also choose from our styles, multi-color specifications are available, to meet various decoration styles.

Scene: Home/Indoor; Office/Enterprise; Hotel/Supermarket.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners