Product Video

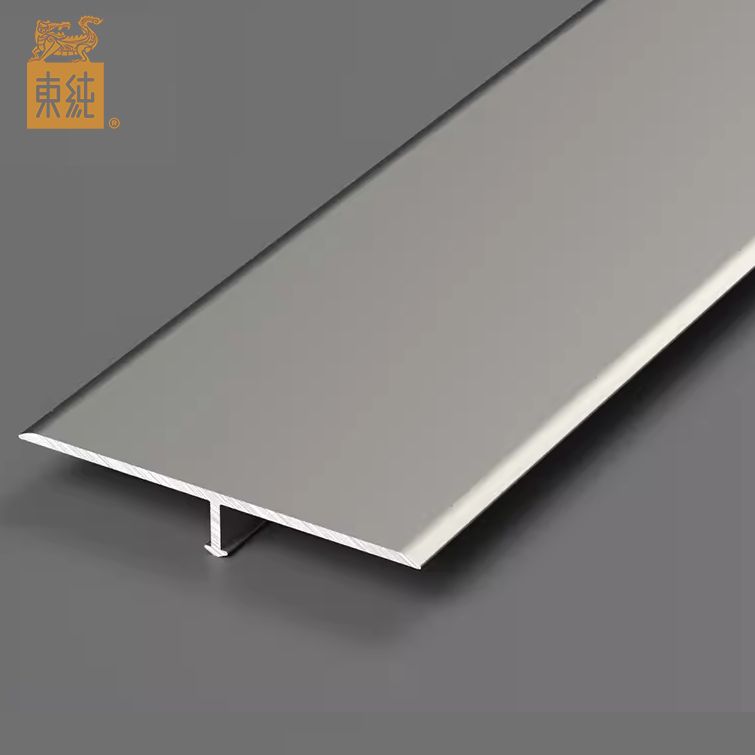

Multiple models of aluminum tile trim, Model No.: 00111/X4/071/351-1, Closed type, Please contact with us for width and height.

Good quality aluminum alloy raw materials after hot extrusion molding, through aging treatment technology to improve the strength and hardness, and spray required color and thermal transfer pattern on the surfaces.

Wear-resistant, anti-aging, anti-oxidation, no cracking

Health and environmental protection, no formaldehyde, no radiation

Waterproof, fireproof, rust proof, moisture proof, moth proof, insect proof

Stronger than traditional acrylic and PVC, strong anti-collision, not easy to deform

Good decorative effect, luxurious and beautiful

Many colors, styles, short production cycle

Our advantages:

1. With all kinds of advanced production and processing equipment, we can produce products of different specifications according to customer requirements, with short production cycle;

2. Has a professional R&D team, team members are skilled and have many years of rich experience;

3. Have a strict and perfect quality management system to ensure the quality of products;

4. With intimate pre-sales and after-sales service, customers have no worries.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners