Product Video

Specification

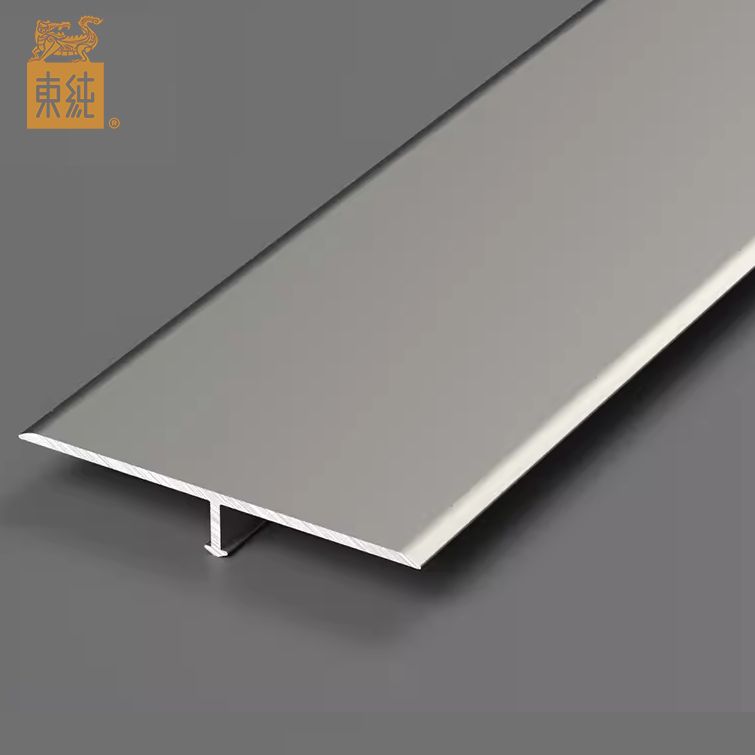

| Products Name | aluminum skirting with LED | |||

| Material | Aluminum Alloy | |||

| Color | Customized | |||

| Length | 2.5mmeters / Customized | |||

| Width | Support Customized | |||

| Height | 50mm / 80mm / Customized | |||

| Surface Treatment | Spray Coating / Anodizing / Porcelain Enamel Coating | |||

| Features | Durability / Lightweight / Aesthetics / Low maintenance / Eco-friendly / Flexibility | |||

| Application | For Wall Base / Wall Foot Protection | |||

| Service | 1. Free Sample; | |||

| 2. OEM Available; | ||||

| 3. Custom-Made Request; | ||||

| 4. New Design Solution Suggestion | ||||

| Payment Terms | Payment<=1000USD, 100% in advance. | |||

| Payment>=1000USD, T/T 30% Deposit In Advance, 70% Balance Before Delivery. | ||||

| Delivery | 15-30days | |||

About Dongchun

Foshan Dongchun building material company, as a professional production factory, specialized in making decorative aluminum profile, including:

1. aluminum tile trim

2. aluminum stair nosing

3. aluminum skirting baseboard

4. aluminum led slot

5. aluminum wall panel trim

We also producing PVC trim and tile adhesive, tile grout and other waterproofing materials.

We have 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

FAQ

1. Can I get some samples?

Can provide small samples for free. Customized sample takes 5-7 days.

2. How about the delivery time?

Container order need 25-30 days.

3.Can I have customized packing with my logo?

Yes, we can follow your design, also we offer different types of packing, like bundle, woven bag, steel crate and wooden pallet / box.

4. How do you control the quality during production?

1) From raw material, forming, polishing, to packaging, we have QC for every process to do inspection, guarentee our products 100% qualified.

2) For mirror finish product, we will polish it as least 4 times.

3) To avoid scratches, after polishing, products will be lay out on a steel crate then we could lift the whole steel crate instead of the product itself.

4) We use the gunny bags twining on machine to protect the product surface when it laying-out.