Product Video

Specification

| Product Name | 10cm matt anodized color wholesale metal baseboard |

| Material | Environmental-friendly aluminum |

| Height | 80/100/120 mm |

| Length | 3m/3.6m/4m customized |

| Thickness | 1.7mm |

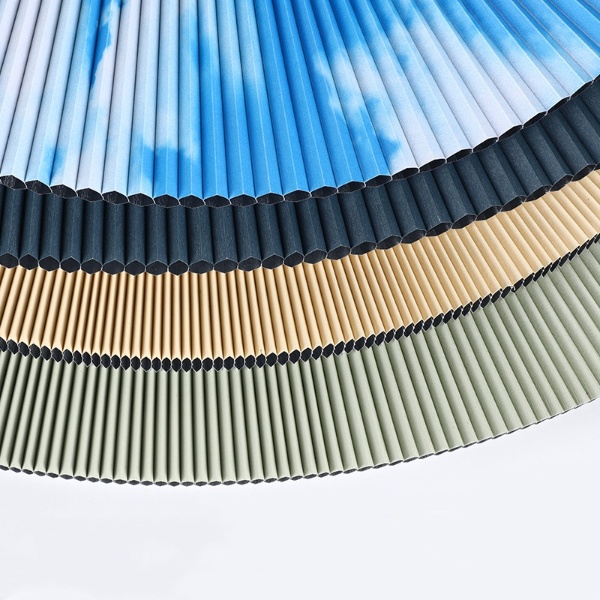

| Finishing | painted, silver, white, black, brown, etc. |

| Application | flooring skirting, kitchen flooring |

| OEM | OEM service available |

| Feature | Economic, waterproof, durable and long lifetime, environmental-friendly |

| Certificate | SGS ROHS |

| Place of origin | GD, CHINA |

| MOQ | 200 pcs |

Discuss

An often overlooked element when it comes to interior design and finishing is baseboards or baseboards. However, with the rise of aluminum baseboards, this humble feature has become a key component in creating an elegant, modern look for any space.

Aluminum baseboards, also known as aluminum baseboards, are a stylish and durable option that protects the bottom edge of walls, covers unsightly gaps, and adds elegance to any room. One of the standout advantages of aluminum baseboards is its ability to withstand wear and tear, making it an excellent investment for high-traffic areas.

One of the key functions of aluminum baseboards is the ability to hide exposed wires and cables. As technology advances and the use of electronics increases in our daily lives, managing cables has become critical. Aluminum baseboards with built-in wire channels provide a neat and organized solution, hiding cables and preventing potential hazards.

FAQ

1. Can I get some samples?

Can provide small samples for free. Customized sample takes 5-7 days.

2. How about the delivery time?

Container order need 25-30 days.

3.Can I have customized packing with my logo?

Yes, we can follow your design, also we offer different types of packing, like bundle, woven bag, steel crate and wooden pallet / box.

4. How do you control the quality during production?

1) From raw material, forming, polishing, to packaging, we have QC for every process to do inspection, guarentee our products 100% qualified.

2) For mirror finish product, we will polish it as least 4 times.

3) To avoid scratches, after polishing, products will be lay out on a steel crate then we could lift the whole steel crate instead of the product itself.

4) We use the gunny bags twining on machine to protect the product surface when it laying-out.